I got sick of mending my truck so last week so I decided to modify instead.

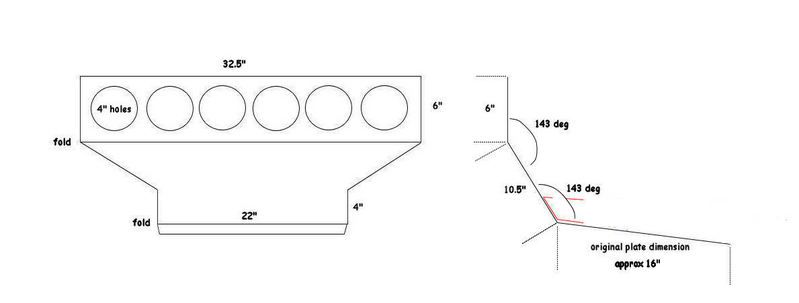

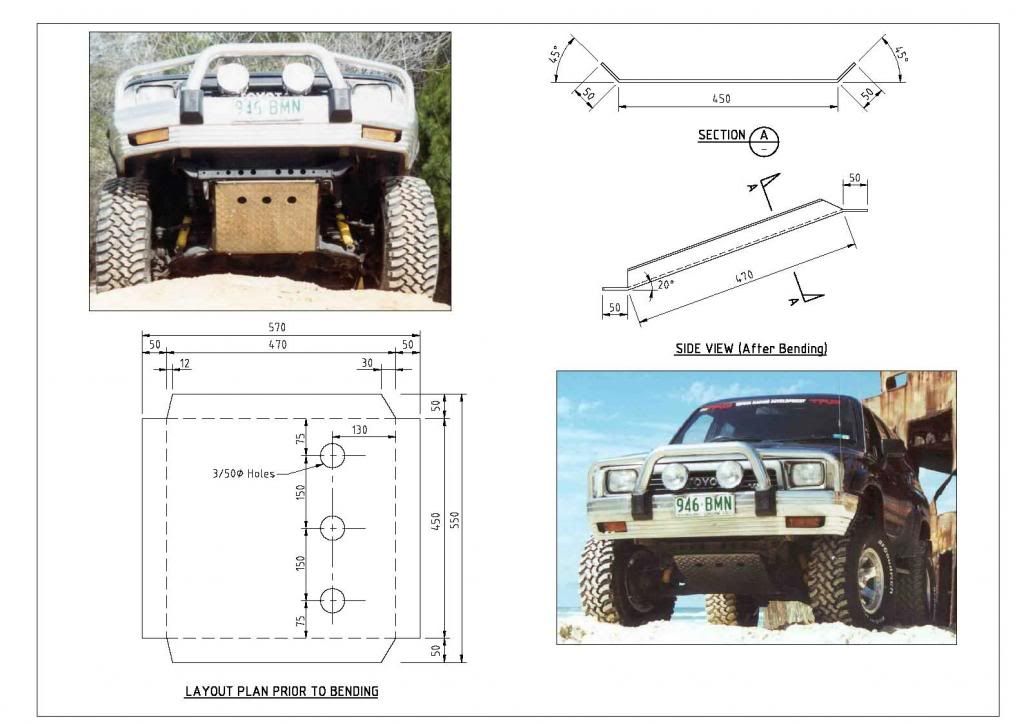

I bought some 4.5mm thick chequered aluminium to beef up my plate and make it look a bit more substantial. It cost me about £24 but it was cut to my measurements which made it a lot easier.

I was advised by some members that a chemical reaction would take place by bolting steel to aluminium. I kept this in mind.

I drilled and provisionally bolted the plate in place then used a vice to curve it inline with the original plate. I also cut access holes for the mounting bolts. My rotary made light work of sanding the back of the plate to give me a key; I sprayed the back with an enamel primer to stop metal to metal contact, making sure I got inside all of the bolt holes.

My bash plate was a bit rough but I cleaned it up and gave it 4 thick coats of hammerite to keep the rust on the inside at bay and to avoid metal to metal contact.

I then bolted the aluminium plate on with copper grease dipped bolts and nylon washers; again to avoid contact. (yes these are the wrong pictures but you get the idea)

It was a bit of a pain to get back on as its a fair amount heavier but I am really pleased with it.

I bought some 4.5mm thick chequered aluminium to beef up my plate and make it look a bit more substantial. It cost me about £24 but it was cut to my measurements which made it a lot easier.

I was advised by some members that a chemical reaction would take place by bolting steel to aluminium. I kept this in mind.

I drilled and provisionally bolted the plate in place then used a vice to curve it inline with the original plate. I also cut access holes for the mounting bolts. My rotary made light work of sanding the back of the plate to give me a key; I sprayed the back with an enamel primer to stop metal to metal contact, making sure I got inside all of the bolt holes.

My bash plate was a bit rough but I cleaned it up and gave it 4 thick coats of hammerite to keep the rust on the inside at bay and to avoid metal to metal contact.

I then bolted the aluminium plate on with copper grease dipped bolts and nylon washers; again to avoid contact. (yes these are the wrong pictures but you get the idea)

It was a bit of a pain to get back on as its a fair amount heavier but I am really pleased with it.

Comment