I'am by no means a expert mechanic but thought i would post a few pics and wright a bit of stuff that may help people in the future

Engine from stormforce expertly rapped thanks Rich

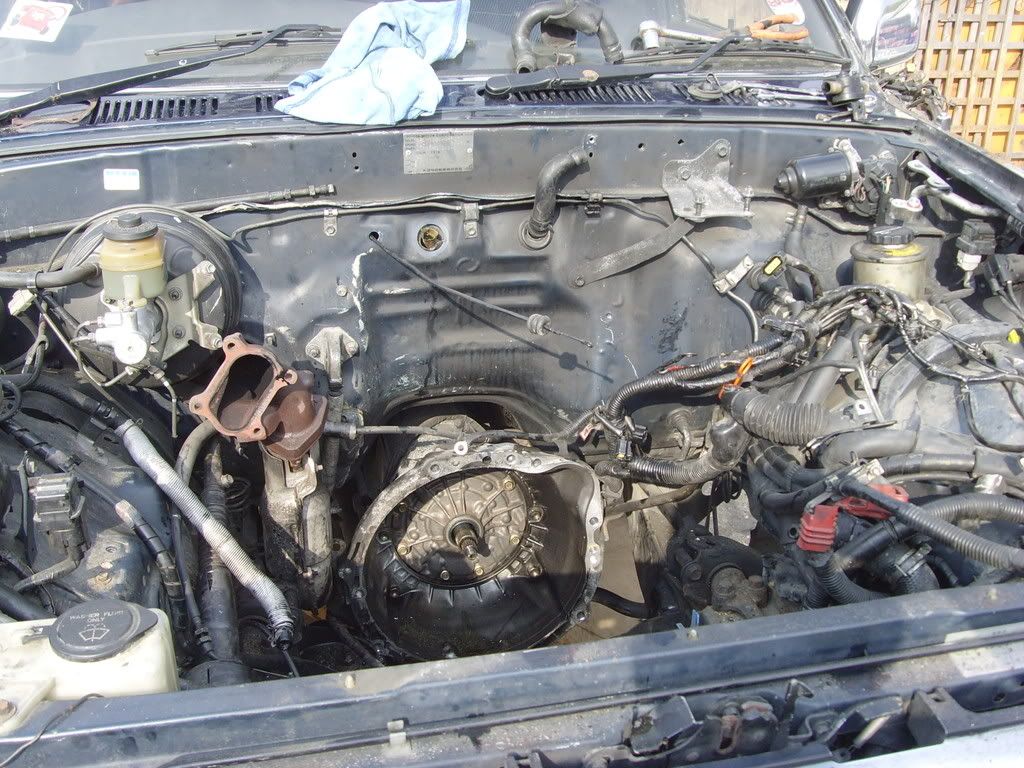

Started to unbolt the old surf today,

Took of air box, batteries, fan, diesel filter and anything else that looks like it's in the way

May sound simple but take the front wheels off, everythings a lot easier

Next to unbolt the torque converter from the fly wheel so the engine lifts out easier

This is a bit fiddily as you only have a small inspection hole at the bottom of the bell housing to undo the six bolts, and you can only see one at a time so you have to keep turning the engine around using a ratchet on the bottom pulley

The only problem is that my engine must have snapped a rod or something coz i could only turn it round so far and only got 4 bolts so that was a waste of time.

Next the easy bolts around the bottom and sides of the bell housing, starter motor and exhaust mount, just leaving the two sods on the top.

Now i'am going to try and undo the engine mounts and drop the engine a bit so i can get too the ones on the top

Engine from stormforce expertly rapped thanks Rich

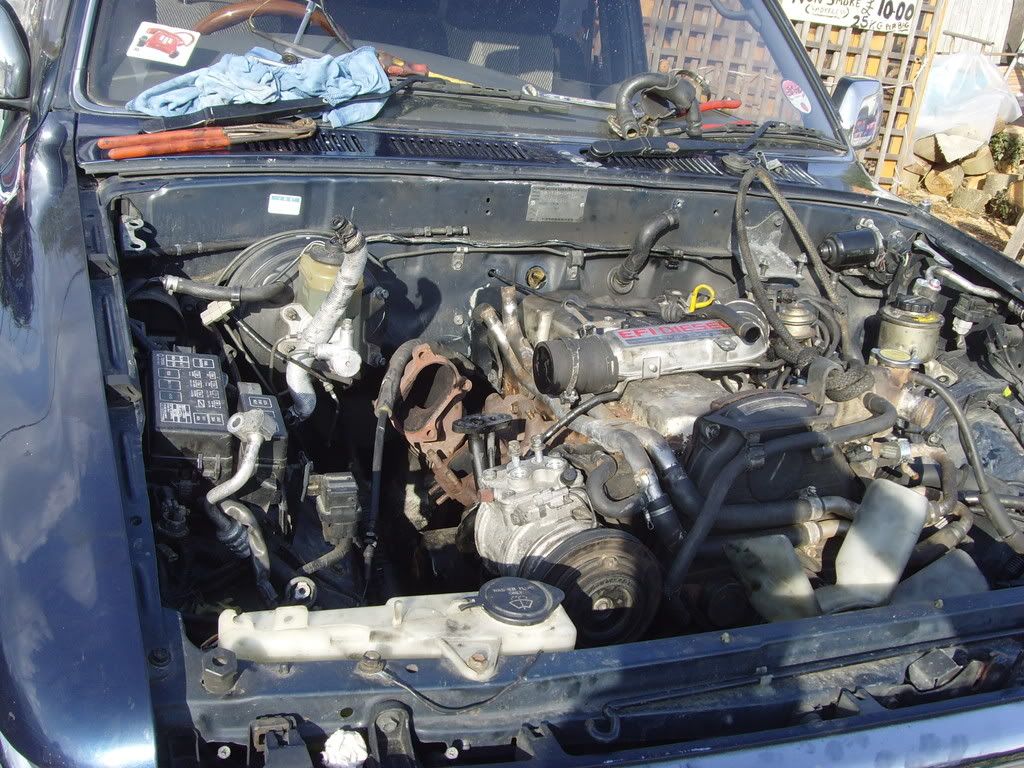

Started to unbolt the old surf today,

Took of air box, batteries, fan, diesel filter and anything else that looks like it's in the way

May sound simple but take the front wheels off, everythings a lot easier

Next to unbolt the torque converter from the fly wheel so the engine lifts out easier

This is a bit fiddily as you only have a small inspection hole at the bottom of the bell housing to undo the six bolts, and you can only see one at a time so you have to keep turning the engine around using a ratchet on the bottom pulley

The only problem is that my engine must have snapped a rod or something coz i could only turn it round so far and only got 4 bolts so that was a waste of time.

Next the easy bolts around the bottom and sides of the bell housing, starter motor and exhaust mount, just leaving the two sods on the top.

Now i'am going to try and undo the engine mounts and drop the engine a bit so i can get too the ones on the top

And i already new that.

And i already new that.

Comment