Originally posted by scott-lee

View Post

Announcement

Collapse

No announcement yet.

@ surfenstien

Collapse

X

-

fear not my lord,i have a cunning planOriginally posted by surfenstein View Postyep. Its nearly there just not quite, i think a couple of mm will make all the difference, actually the difference being it fitting and not fitting.lol

im getting an upper ball joint on friday,from RT

i'll get it redrawn ,by the cad-cam boy's,scale 1:1, cut it out,and see if it fits.

simples.

Comment

-

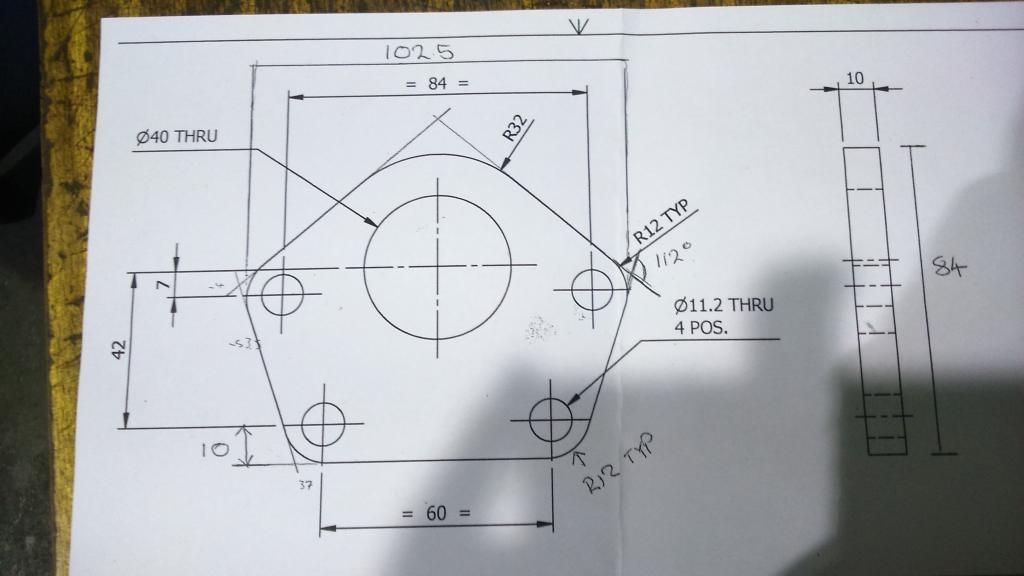

well,this is the drawing we made from the spacers you had.

the holes are in the right place,same as the drawing ian put up, mine are bigger,but i guess that wont affect location,as the center hole is the same.

they are the same,otherwise.

so im baffled as to the 4mm out .

Comment

-

cheer,mate. was thinking i might lacquer them.

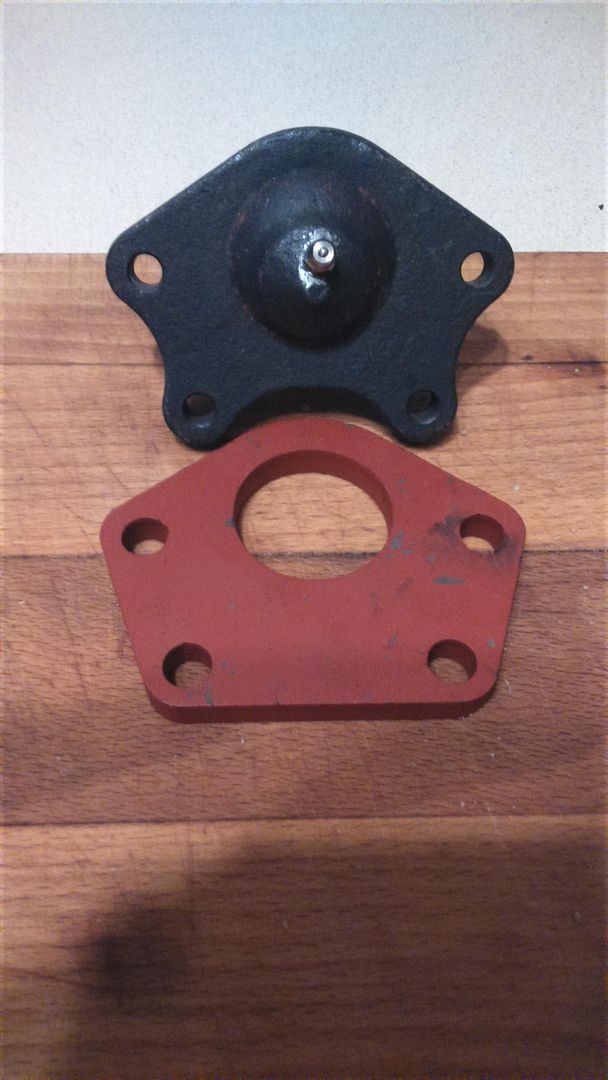

barry gave me an old ball joint when i popped in today,as a tester,bless him.

got to say,its not looking good ,mate.looks like all 3 drawings are wrong,but i'll know for sure tomorrow when i see the guys.

got another car full of metal for you too, some nice chunky box section,which may have come in handy 3 weeks ago,sadly.

rumour has it,our spare unit has pallets of it,just going idle.

i'll be on that next week,for sure!

Comment

-

I though the drawings were wrong. The ball on the joint is bigger than the drawing said it was. Awesome on the metal mate, you can never have too much of that lying around.The only problem with lacquer is it turns yellow after a short period of time.Originally posted by scott-lee View Postcheer,mate. was thinking i might lacquer them.

barry gave me an old ball joint when i popped in today,as a tester,bless him.

got to say,its not looking good ,mate.looks like all 3 drawings are wrong,but i'll know for sure tomorrow when i see the guys.

got another car full of metal for you too, some nice chunky box section,which may have come in handy 3 weeks ago,sadly.

rumour has it,our spare unit has pallets of it,just going idle.

i'll be on that next week,for sure! www.overfab.uk

www.overfab.uk

Comment

-

i reckon the hole needs to be 43mm,at least,and going by all the drawings i have, its 7mm above the side bolt holes (centurally speaking) i think the hole centers for the big,and side bolt holes should be level (so move datum hole down 7mm)

Comment

-

i have handed all the drawings and parts over to the technical design guys at work should have a drawing by the end of the week.making the center hole 44mm to allow for the radius on the bottom of the cast dome on the BJ,and close the holes down to 10mm,we are just working out how much to drop the center hole down,to get it spot on.i may have to take time off work this week,as my new meds really dont seem to working for me,but should be in at the end of the week to check on it.

are you and stinger still going to be able to sort out the springs and coils on saturday,for me?

having both cars being worked on,thursday and friday, doing the coolant flush you reccomended to the truck friday afternoon, want to be there so i can check on how my mechanic does it.

so many stories on here how that gets cocked up,i am not looking forward to it!

Comment

Comment