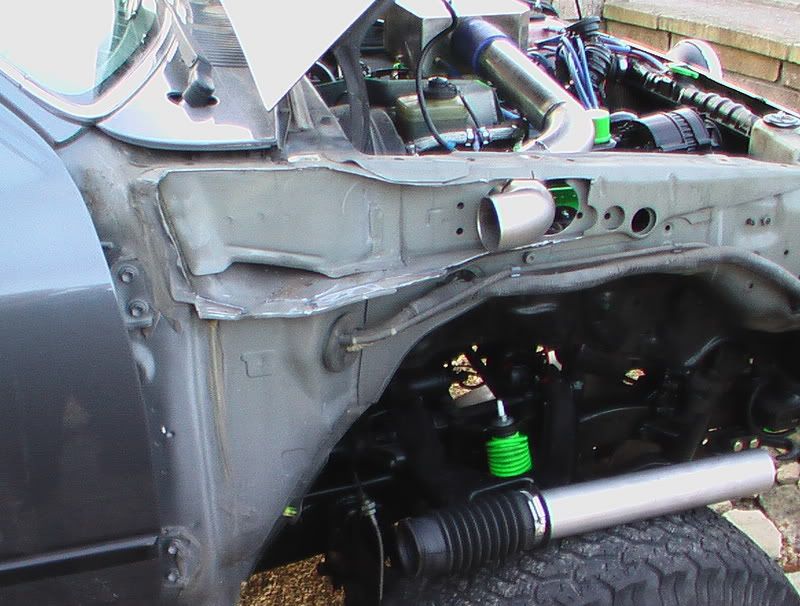

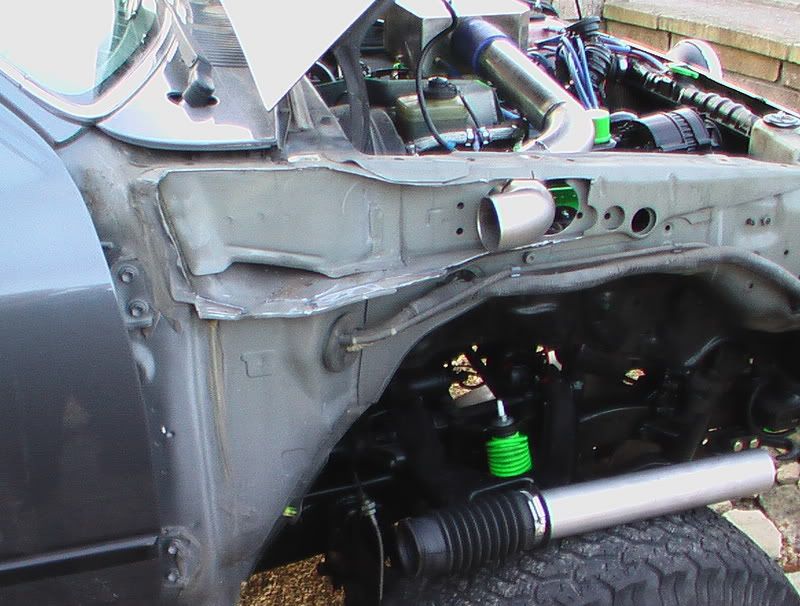

seeing as it was such a lovely evening i decided to start the other side of the snorkel early.ill post the finished pics tomorrow.but heres a sneaky peek at the progress so far.

)

)

but i will take your point into account.ian did give me some very nice concertina hoses.so if they do hit ill swap them over.

but i will take your point into account.ian did give me some very nice concertina hoses.so if they do hit ill swap them over.

Comment